Do you have a passion for asset protection and Walmart? Continue reading to learn more about these roles and the safety procedures involved. Once you are convinced that Walmart is the right place for you, apply today. Learn more about Walmart's Asset Protection Associate Salary, Compensation and Safety Procedures. Also, learn more about the benefits of this position. Complete the online application to find out more. You will need an account to get started.

Walmart associates in asset protection

Walmart Asset Protection Associate salaries range from Rs 1.8 Lakhs to Rs 2.2 Lakhs annually. This salary is calculated using statistical methods as well as actual salaries from 6 employees. The following information will help you learn more about the job. The following information is based on 6 anonymously submitted salaries to Glassdoor by Asset Protection Associates. This information does include bonuses, overtime and any other compensation.

For this job, people with criminal justice backgrounds and experience in retail loss prevention will be a good fit. Walmart offers many career opportunities and salary ranges to asset protection associates. Walmart Careers offers job descriptions and information about job responsibilities. You can apply by signing the disclosures. If you are applying for a position as an AP manager, you will need to fill out an online application and upload a copy of your resume.

Safety procedures

Walmart is one the most important and diverse retailers in the United States. This means that there are many safety and security issues. The following are the safety procedures and top priorities of Walmart's Asset Protection program. Mike Lamb, vice president of Walmart US's asset protection and safety department, explains how these policies help protect Walmart's assets, while addressing the most common problems and opportunities. This program assists associates in protecting the company's resources and keeping customers as well as associates safe.

Associate: Walmart Asset Protection Program Associates are the frontline of crime prevention. They help store managers and employees keep their stores safe from theft and fraud. While there are no formal requirements for entry-level positions, managers must have a Bachelor's degree in criminal justice or a Loss Prevention Qualified Certificate. A Loss Prevention Qualified Certificate does not apply to entry-level positions. However, a degree or certificate in criminal justice is highly beneficial.

Compensation

Based on 974 employees with the same job title, Walmart Asset Protection's average annual compensation is $33,000. This figure includes tips, taxes, bonuses, and wages. It can vary depending upon education and experience. This information is anonymized and is not representative the actual salary for Walmart Asset Protection employees. It does provide a starting point for you to figure the salary you're entitled to.

Wal-Mart awards store managers bonuses that are tied with store performance, even though this is not the case. Walmart recognizes the importance of long-term employees receiving raises over those who are just starting. As such, associates who have many years of work experience can request raises at least once a year. The average hourly salary ranges between $12 and $16. The following table outlines the typical Walmart Ap Customer Host salary. You can find more information on the Walmart official website.

FAQ

How can we improve manufacturing efficiency?

First, identify the factors that affect production time. Then we need to find ways to improve these factors. If you don't know where to start, then think about which factor(s) have the biggest impact on production time. Once you have identified them, it is time to identify solutions.

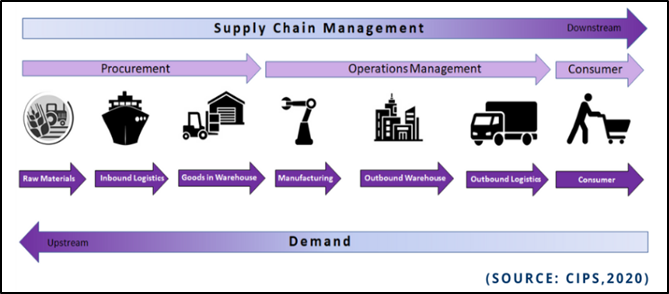

What does it take for a logistics enterprise to succeed?

You need to have a lot of knowledge and skills to manage a successful logistic business. You must have good communication skills to interact effectively with your clients and suppliers. You should be able analyse data and draw inferences. You will need to be able handle pressure well and work in stressful situations. To improve efficiency, you must be innovative and creative. Strong leadership qualities are essential to motivate your team and help them achieve their organizational goals.

You should also be organized and efficient to meet tight deadlines.

How can manufacturing overproduction be reduced?

Better inventory management is key to reducing excess production. This would reduce the amount of time spent on unnecessary activities such as purchasing, storing, and maintaining excess stock. We could use these resources to do other productive tasks.

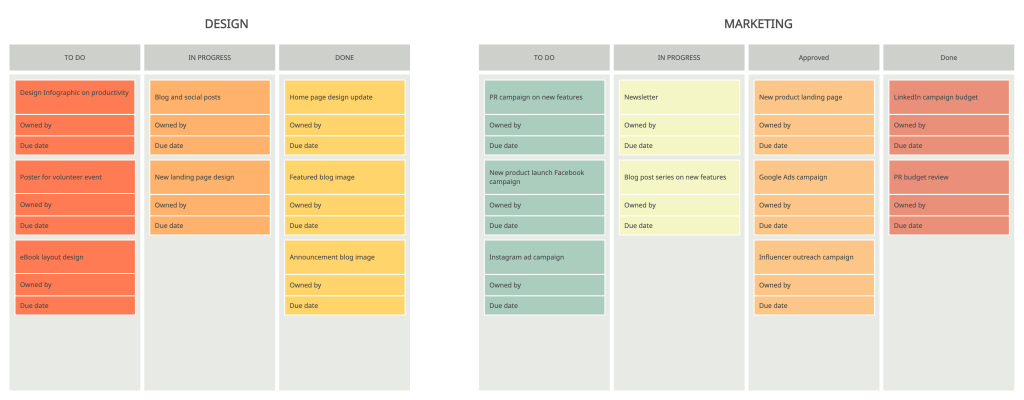

This can be done by using a Kanban system. A Kanban Board is a visual display that tracks work progress. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state has a different priority level.

If work is moving from one stage to the other, then the current task can be completed and moved on to the next. However, if a task is still at the beginning stages, it will remain so until it reaches the end of the process.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. Managers can see how much work has been done and the status of each task at any time with a Kanban Board. This data allows them adjust their workflow based upon real-time data.

Lean manufacturing, another method to control inventory levels, is also an option. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Anything that does not contribute to the product's value is considered waste. These are some of the most common types.

-

Overproduction

-

Inventory

-

Packaging not required

-

Excess materials

Manufacturers can increase efficiency and decrease costs by implementing these ideas.

Is there anything we should know about Manufacturing Processes prior to learning about Logistics.

No. No. Knowing about manufacturing processes will help you understand how logistics works.

What jobs are available in logistics?

There are many kinds of jobs available within logistics. These are some of the jobs available in logistics:

-

Warehouse workers - They load trucks and pallets.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers – They sort and package freight at warehouses.

-

Inventory managers - They oversee the inventory of goods in warehouses.

-

Sales representatives: They sell products to customers.

-

Logistics coordinators – They plan and coordinate logistics operations.

-

Purchasing agents – They buy goods or services necessary to run a company.

-

Customer service representatives - Answer calls and email from customers.

-

Shipping clerks – They process shipping orders, and issue bills.

-

Order fillers - These people fill orders based on what has been ordered.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others – There are many other types available in logistics. They include transport supervisors, cargo specialists and others.

Are there ways to automate parts of manufacturing?

Yes! Automation has been around since ancient times. The Egyptians invented the wheel thousands of years ago. Nowadays, we use robots for assembly lines.

In fact, there are several applications of robotics in manufacturing today. These include:

-

Robots for assembly line

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots create products

Automation could also be used to improve manufacturing. 3D printing is a way to make custom products quickly and without waiting weeks or months for them to be manufactured.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to use the Just-In Time Method in Production

Just-intime (JIT), a method used to lower costs and improve efficiency in business processes, is called just-in-time. It is a process where you get the right amount of resources at the right moment when they are needed. This means that you only pay the amount you actually use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He observed how workers were paid overtime if there were delays in their work. He decided to ensure workers have enough time to do their jobs before starting work to improve productivity.

The idea behind JIT is that you should plan ahead and have everything ready so you don't waste money. Also, you should look at the whole project from start-to-finish and make sure you have the resources necessary to address any issues. You'll be prepared to handle any potential problems if you know in advance. This way you won't be spending more on things that aren’t really needed.

There are different types of JIT methods:

-

Demand-driven: This is a type of JIT where you order the parts/materials needed for your project regularly. This will enable you to keep track of how much material is left after you use it. It will also allow you to predict how long it takes to produce more.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows you predict the amount you can expect to sell.

-

Project-driven: This method allows you to set aside enough funds for your project. If you know the amount you require, you can buy the materials you need.

-

Resource-based JIT: This type of JIT is most commonly used. You allocate resources based on the demand. For instance, if you have a lot of orders coming in, you'll assign more people to handle them. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based pricing: This is similar in concept to cost-based but instead you look at how much each worker costs, it looks at the overall company's price.

-

Material-based - This is a variant of cost-based. But instead of looking at the total company cost, you focus on how much raw material you spend per year.

-

Time-based: This is another variation of resource-based JIT. Instead of focusing solely on the amount each employee costs, focus on how long it takes for the project to be completed.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of focusing on the cost of each worker or how long it takes, think about how high quality your product is.

-

Value-based JIT is the newest form of JIT. In this case, you're not concerned with how well the products perform or whether they meet customer expectations. Instead, you're focused on how much value you add to the market.

-

Stock-based: This is an inventory-based method that focuses on the actual number of items being produced at any given time. It's used when you want to maximize production while minimizing inventory.

-

Just-in-time planning (JIT): This is a combination JIT and supply-chain management. It refers to the process of scheduling the delivery of components as soon as they are ordered. It's important because it reduces lead times and increases throughput.