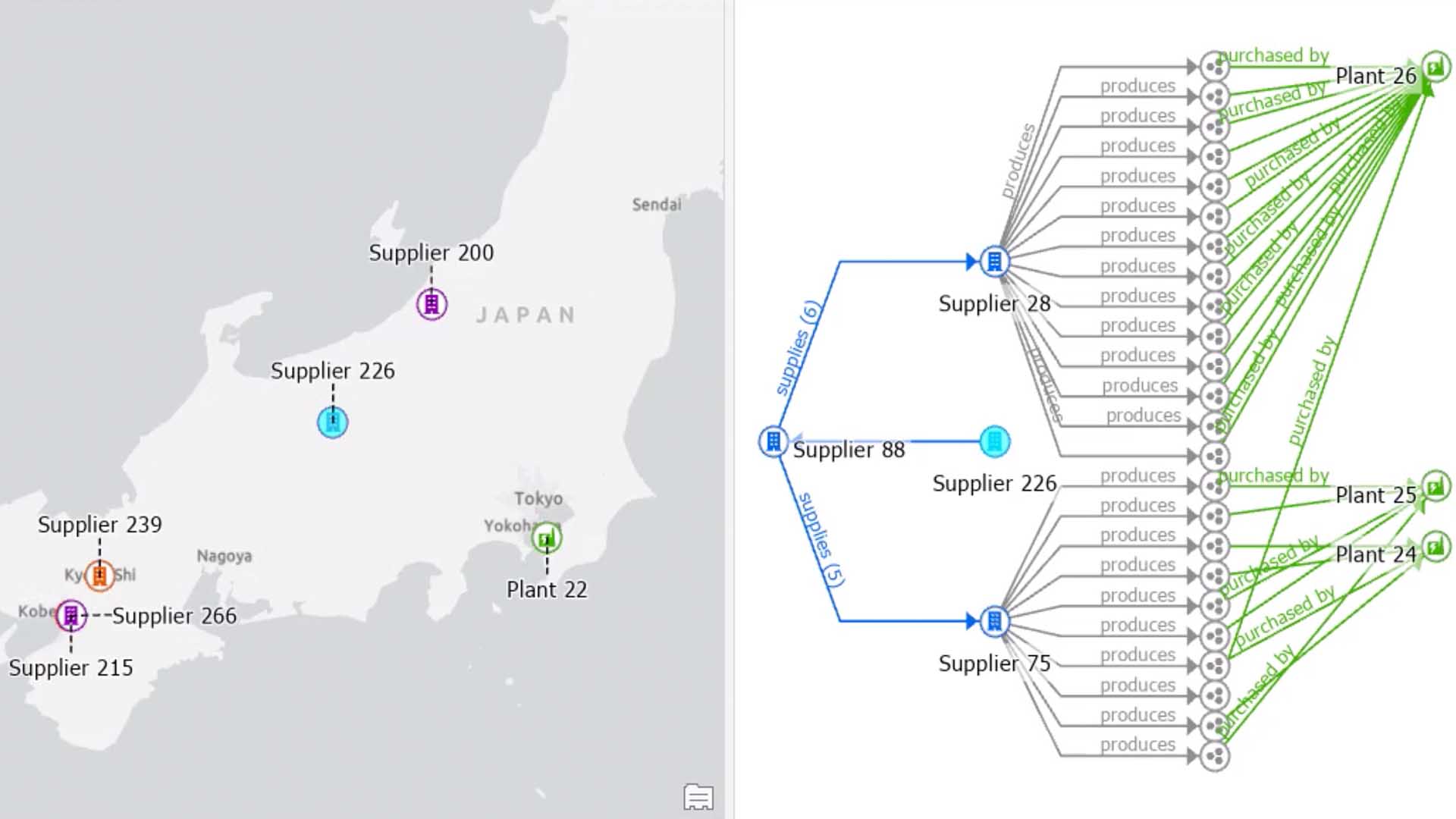

Mexico was one the major actors in DVA's trade network for global manufacturing exports, during the period under analysis. The automotive sector has not taken the same path as the textiles and apparel industry. However, both industries are considered key players in the export market and are still relevant for job generation in Mexico.

The Mexican automotive industry is a major supplier of parts for American automobiles. It is also one among the fastest-growing industries in Mexico. It hasn't been able pull the rest the economy on a high growth trajectory. The automotive industry is transitioning from a domestic-oriented industry into a regional car parts/automobile retailer. This is due to a combination regional processes and foreign direct investments.

Mexico has many programs that have helped the automotive industry. It has become the most important supplier of U.S. auto parts and has experienced remarkable penetration into global markets. It also has received foreign direct investment which has helped to increase its position in global value chains.

Mexico's automotive industry is also a major player in the GVCs of Europe, the United States and other countries. The automotive industry has been an important part of Mexico's economy during the 1970s and 1980s. But it has not had the same penetration into the world market as textiles. It has not been able expand its output at a rapid pace, but it has seen remarkable penetration on the world market.

To analyse the relationship of international trade with labour in Mexico's manufacturing sector, the study uses the ILO framework of decent job indicators. The indicators are based upon official data and take into account the connections between Mexican labour regulations and trade agreements. The indicators also include the input-output analysis of international trade, which shows that Mexico plays a relatively small role in the domestic value-added of global manufacturing exports.

The study also examines how trade liberalization affects employment in Mexico's manufacturing industry. Using the System of National Accounts (SNA) framework, the study constructs a set of decent work indicators for two industrial activities in Mexico: transport equipment and textiles. The study constructs a series of indicators over time, and then uses them to analyze the evolution of decent labor in Mexico. The study finds that the level of D V A G V C in the manufacturing sector is considerably lower than in the textile sector. The study also finds that the level o employment in auto industry is lower than that in the textiles sector. The study also shows that real wages have declined over the period of the analysis. The nominal wage adjustment did not compensate for the decline in real wages. The study shows that DVA in exports for transport equipment has increased in recent years, while DVA has decreased in exports for textiles.

FAQ

What skills are required to be a production manager?

To become a successful production planner, you need to be organized, flexible, and able to multitask. Also, you must be able and willing to communicate with clients and coworkers.

How does a Production Planner differ from a Project Manager?

The major difference between a Production Planner and a Project Manager is that a Project Manager is often the person responsible for organizing and planning the entire project. While a Production Planner is involved mainly in the planning stage,

What kind of jobs are there in logistics?

There are many types of jobs in logistics. Here are some:

-

Warehouse workers – They load, unload and transport pallets and trucks.

-

Transportation drivers - They drive trucks and trailers to deliver goods and carry out pick-ups.

-

Freight handlers - They sort and pack freight in warehouses.

-

Inventory managers – They manage the inventory in warehouses.

-

Sales representatives - They sell products.

-

Logistics coordinators: They plan and manage logistics operations.

-

Purchasing agents - They buy goods and services that are necessary for company operations.

-

Customer service representatives are available to answer customer calls and emails.

-

Shipping clerks – They process shipping orders, and issue bills.

-

Order fillers are people who fill orders based only on what was ordered.

-

Quality control inspectors - They check incoming and outgoing products for defects.

-

Others - There are many other types of jobs available in logistics, such as transportation supervisors, cargo specialists, etc.

How can I learn about manufacturing?

You can learn the most about manufacturing by getting involved in it. You can read books, or watch instructional videos if you don't have the opportunity to do so.

What are the requirements to start a logistics business?

To be a successful businessman in logistics, you will need many skills and knowledge. For clients and suppliers to be successful, you need to have excellent communication skills. It is important to be able to analyse data and draw conclusions. You will need to be able handle pressure well and work in stressful situations. To improve efficiency, you must be innovative and creative. You need to have strong leadership qualities to motivate team members and direct them towards achieving organizational goals.

You must be organized to meet tight deadlines.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

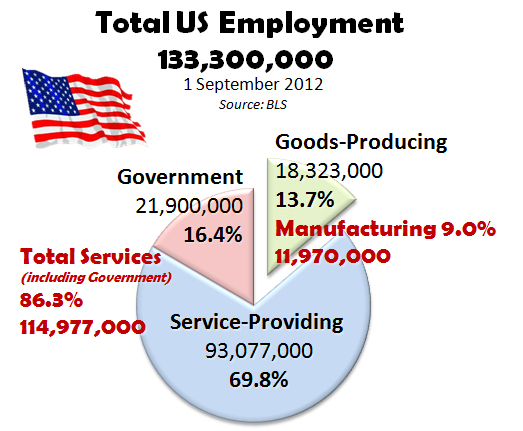

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to Use Lean Manufacturing in the Production of Goods

Lean manufacturing is an approach to management that aims for efficiency and waste reduction. It was first developed in Japan in the 1970s/80s by Taiichi Ahno, who was awarded the Toyota Production System (TPS), award from KanjiToyoda, the founder of TPS. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

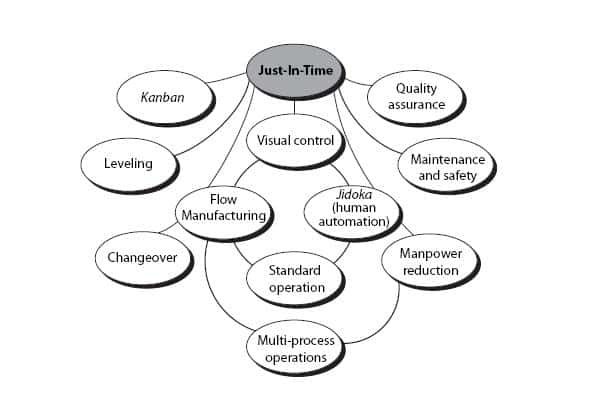

Lean manufacturing is often described as a set if principles that help improve the quality and speed of products and services. It emphasizes eliminating waste and defects throughout the value stream. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Many industries worldwide use lean manufacturing. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Lean manufacturing is based on five principles:

-

Define Value- Identify the added value your company brings to society. What makes you stand out from your competitors?

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize & Simplify - Make processes as consistent and repeatable as possible.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Although lean manufacturing has always been around, it is gaining popularity in recent years because of a renewed interest for the economy after 2008's global financial crisis. Many companies have adopted lean manufacturing methods to increase their marketability. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing is becoming a popular practice in automotive. It has many advantages. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

The principles of lean manufacturing can be applied in almost any area of an organization. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three main types:

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT stands for a system where components are assembled on the spot rather than being made in advance. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. It is better to repair a part than have it removed from the production line if it needs to be fixed. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI: Continuous improvement aims to increase the efficiency of operations by constantly identifying and making improvements to reduce or eliminate waste. Continuous improvement involves continuous improvement of processes and people as well as tools.