Toyota has always maintained its core goal of making high quality products, regardless of its success. Its unwavering commitment to excellence has helped Toyota become one of the world's top automotive brands.

Toyota's strategy is built on its core values and encourages smart growth. It also emphasizes the importance of developing and nurturing relationships with its dealers. While other companies may choose to rely on their stock price, Toyota makes its customers the priority. Because the automobile industry can be very competitive and companies' success is dependent on their ability to innovate, Toyota does this.

In order to maintain its success, Toyota employees have to grapple with challenges. Toyota encourages employees in this area to explore and create new ideas. Employees are encouraged to communicate openly and challenged to make compromises and transcend differences. On-thejob training helps to accomplish this. Employees should also be encouraged to admit their failures and shortcomings.

Another way Toyota manages to succeed is through the use of a "continuous improvement" process, called kaizen. This involves streamlining processes as well as testing new ideas. Known in Japanese as genchi genbutsu, this process helps Toyota to achieve its goals. It is also an integral part Toyota's culture. It has been the core of Toyota's success since decades.

Toyota started a research lab as one of its major moves. Its founder, Kiichiro Toyoda, believed that if the automobile industry was to remain competitive, it would need to develop new technologies from scratch. In the late 1930s, he set up a research facility. He envisioned a world where Japan would produce its own automobiles and automobile technology without foreign technology.

In the 1950s, Toyota made a series of strategic moves. It expanded its product range and exported cars to many countries. It established a separate sales organization and a network for dealers. It also started to gain an understanding of international automobile markets. It was able to see that American and European automakers would overtake Toyota if Toyota attempted to compete in the global market.

Toyota's decision to establish a division in America was another major move it made in the 1950s. It did this because it realized that American workers are nine times more productive then Japanese workers. It realized that the market demanded fuel-efficient cars. It had to convince Americans that Japanese cars were worth the investment. It also had to overcome a massive strike that almost bankrupted it in the 1950s. It was forced to borrow money and reduce staff.

Toyota also launched a driver training school for citizens to help them get their licenses. The company also made a range of cars that are specifically designed for the U.S. marketplace. These initiatives helped it attract customers to its dealers.

Toyota's success is dependent upon its ability to innovate and create value. It is also dependent upon its ability build relationships with suppliers.

FAQ

How can manufacturing prevent production bottlenecks?

Production bottlenecks can be avoided by ensuring that processes are running smoothly during the entire production process, starting with the receipt of an order and ending when the product ships.

This includes planning to meet capacity requirements and quality control.

Continuous improvement techniques like Six Sigma are the best way to achieve this.

Six Sigma is a management system used to improve quality and reduce waste in every aspect of your organization.

It seeks to eliminate variation and create consistency in your work.

What can I do to learn more about manufacturing?

Practical experience is the best way of learning about manufacturing. However, if that's not possible, you can always read books or watch educational videos.

What is production planning?

Production planning is the process of creating a plan that covers all aspects of production. This includes scheduling, budgeting and crew, location, equipment, props, and more. This document ensures that everything is prepared and available when you are ready for shooting. This document should also include information on how to get the best result on set. This includes information on shooting times, locations, cast lists and crew details.

The first step is to outline what you want to film. You may have decided where to shoot or even specific locations you want to use. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. For example, you might decide that you need a car but don't know exactly what model you want. If this is the case, you might start searching online for car models and then narrow your options by selecting from different makes.

After you've found the perfect car, it's time to start thinking about adding extras. What about additional seating? Maybe you need someone to move around in the back. Maybe you'd like to change the interior from black to a white color. These questions will help you determine the exact look and feel of your car. You can also think about the type of shots you want to get. Are you going to be shooting close-ups? Or wide angles? Perhaps you want to show the engine or the steering wheel? These details will help identify the exact car you wish to film.

Once you have determined all of the above, you can move on to creating a schedule. The schedule will show you when to begin shooting and when to stop. Each day will include the time when you need to arrive at the location, when you need to leave and when you need to return home. This way, everyone knows what they need to do and when. If you need to hire extra staff, you can make sure you book them in advance. There is no point in hiring someone who won't turn up because you didn't let him know.

Also, consider how many days you will be filming your schedule. Some projects are quick and easy, while others take weeks. While creating your schedule, it is important to remember whether you will require more than one shot per day. Shooting multiple takes over the same location will increase costs and take longer to complete. If you aren't sure whether you need multiple shots, it is best to take fewer photos than you would like.

Budgeting is another important aspect of production planning. A realistic budget will help you work within your means. Remember that you can always reduce the budget later on if you run into unforeseen problems. However, it is important not to overestimate the amount that you will spend. Underestimating the cost will result in less money after you have paid for other items.

Production planning is a very detailed process, but once you understand how everything works together, it becomes easier to plan future projects.

How can manufacturing overproduction be reduced?

In order to reduce excess production, you need to develop better inventory management methods. This would reduce the time needed to manage inventory. We could use these resources to do other productive tasks.

You can do this by adopting a Kanban method. A Kanban board is a visual display used to track work in progress. A Kanban system allows work items to move through several states before reaching their final destination. Each state represents an individual priority level.

For instance, when work moves from one stage to another, the current task is complete enough to be moved to the next stage. However, if a task is still at the beginning stages, it will remain so until it reaches the end of the process.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. A Kanban board allows managers to monitor how much work is being completed at any given moment. This information allows managers to adjust their workflow based off real-time data.

Another way to control inventory levels is to implement lean manufacturing. Lean manufacturing seeks to eliminate waste from every step of the production cycle. Any product that isn't adding value can be considered waste. The following are examples of common waste types:

-

Overproduction

-

Inventory

-

Packaging not required

-

Excess materials

These ideas can help manufacturers improve efficiency and reduce costs.

What is the job of a production plan?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. They also ensure that the product/service meets the client’s needs.

What are the jobs in logistics?

There are many kinds of jobs available within logistics. Some of them are:

-

Warehouse workers - They load trucks and pallets.

-

Transport drivers - These are people who drive trucks and trailers to transport goods or perform pick-ups.

-

Freight handlers, - They sort out and pack freight in warehouses.

-

Inventory managers – They manage the inventory in warehouses.

-

Sales representatives: They sell products to customers.

-

Logistics coordinators are responsible for organizing and planning logistics operations.

-

Purchasing agents – They buy goods or services necessary to run a company.

-

Customer service representatives - They answer calls and emails from customers.

-

Shipping clerks – They process shipping orders, and issue bills.

-

Order fillers – They fill orders based upon what was ordered and shipped.

-

Quality control inspectors - They check incoming and outgoing products for defects.

-

Others – There are many other types available in logistics. They include transport supervisors, cargo specialists and others.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use Lean Manufacturing in the Production of Goods

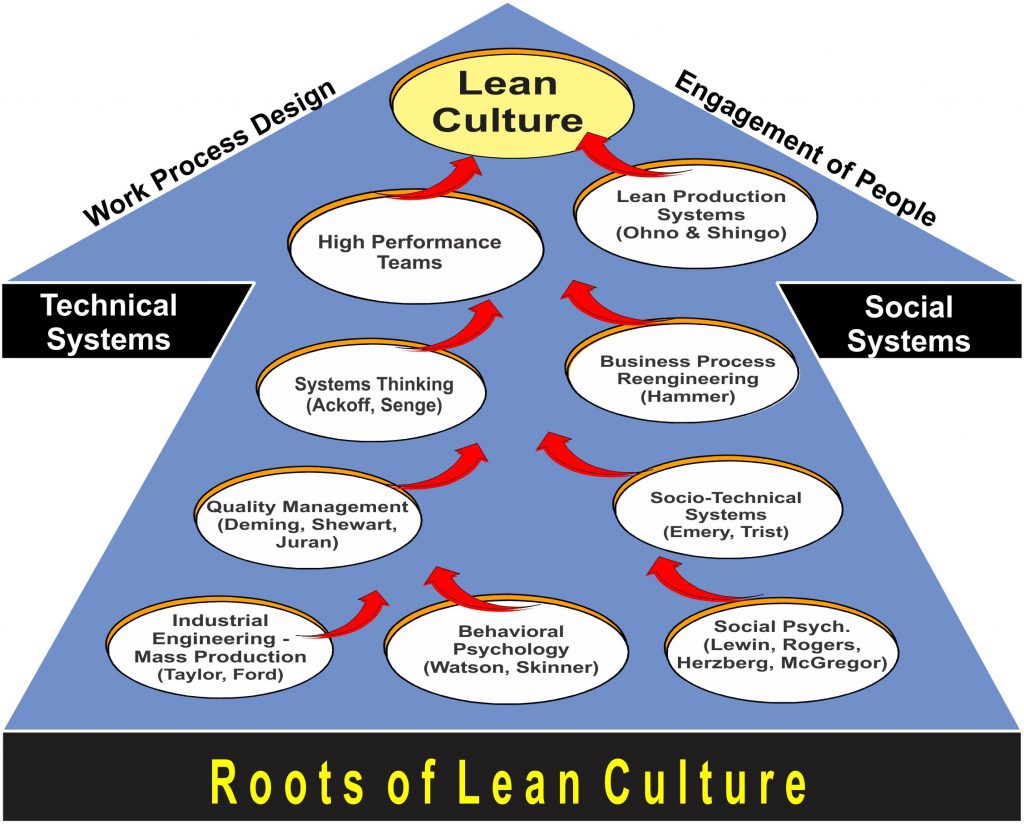

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes the elimination and minimization of waste in the value stream. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean Manufacturing is one of the most efficient ways to manage the entire value chains, including suppliers and customers as well distributors and retailers. Many industries worldwide use lean manufacturing. For example, Toyota's philosophy underpins its success in automobiles, electronics, appliances, healthcare, chemical engineering, aerospace, paper, food, etc.

Five principles are the basis of lean manufacturing:

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce waste - Get rid of any activity that does not add value to the supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Building Relationships – Establish personal relationships with both external and internal stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many businesses have adopted lean manufacturing techniques to help them become more competitive. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing, which has many benefits, is now a standard practice in the automotive industry. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

The principles of lean manufacturing can be applied in almost any area of an organization. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three main types of lean manufacturing:

-

Just-in-Time Manufacturing (JIT): This type of lean manufacturing is commonly referred to as "pull systems." JIT refers to a system in which components are assembled at the point of use instead of being produced ahead of time. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. Repairing a part that is damaged during assembly should be done, not scrapping. This also applies to finished products that need minor repairs before being shipped.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous improvement involves continuous improvement of processes and people as well as tools.