It can be difficult to provide logistics services in Alaska. Alaska has unique logistical challenges, from the harsh climate to the rugged terrain. It is also the least populated state in the United States. Transportation options are very limited in Alaska during certain months. Fortunately, Alaska is home to a wide array of logistics companies that can help to move your goods around the state. These services include freight forwarding and intermodal transport.

One of the largest logistics providers in Alaska is the Port of Alaska. This gateway serves 85% of the state's population. It is the only reliable gateway to large-volume freight delivery to Anchorage or Fairbanks. Port of Alaska not only serves as a major hub for cargo transport, but also offers support to the seafood industry.

CP Logistics, an Alaska logistics provider, has a significant effect on the state. This company provides supply chain management service throughout the United States, Canada, Caribbean. The company uses third-party audits to ensure quality and safety. The company has an SQF food safety policy. This company is a leader in logistics and has just launched a mobile app that provides real-time shipment data.

Carlile Logistics is another logistics company worth looking into. This company offers truck cabs and fuel tankers as well as cargo trailers. The company belongs to the Saltchuk Resources Group of Companies. It is a company that places great emphasis on innovation, technology, and the environment. Alaska-based, the company supports various projects, from building projects to oil exploration. In addition, the company is constantly looking to meet changing client needs.

PRL Logistics Inc. is another notable Alaska logistics company. This company provides logistical assistance to Gallagher Marine Systems. The company is a well-known provider of logistics services in Alaska. They have worked alongside companies like PenAir, Bristow Aviation, DHL, and Bristow Aviation. Their team has worked in the Aleutians as well as the Southeast.

Another logistics company that has made a big splash in Alaska is Alaska Logistics, LLC. Alaska Logistics LLC offers container and barge transport to Alaska customers. They have also expanded their services to transport other types of cargo. They offer everything from transport of bulk commodities to barges and containers. They serve the ports of Western Alaska and nearby villages.

The most important aspect of any logistics company in Alaska is that they have a strong reputation for providing quality service. It is vital to be ready for anything. Alaska is known for its extreme weather. There are also risks of flooding and eruptions from volcanoes. This can lead to major damage. In addition, the state has a limited highway system. As a result, logistics providers need to be prepared to handle all of the state's logistical challenges.

Moving cement is also a major logistical challenge in Alaska. Cement is needed for construction projects, and often needs to be transported by air. This can be tricky, so it is worth planning ahead.

FAQ

What is the role of a production manager?

A production planner ensures all aspects of the project are delivered on time, within budget, and within scope. They also ensure the quality of the product and service meets the client's requirements.

What is the role of a manager in manufacturing?

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They should also be aware and responsive to any company problems.

They should also learn how to communicate effectively with other departments, including sales and marketing.

They must also keep up-to-date with the latest trends in their field and be able use this information to improve productivity and efficiency.

What can I do to learn more about manufacturing?

You can learn the most about manufacturing by getting involved in it. However, if that's not possible, you can always read books or watch educational videos.

What are the requirements to start a logistics business?

It takes a lot of skills and knowledge to run a successful logistics business. To communicate effectively with clients and suppliers, you must be able to communicate well. You will need to know how to interpret data and draw conclusions. You will need to be able handle pressure well and work in stressful situations. In order to innovate and create new ways to improve efficiency, creativity is essential. You must be a strong leader to motivate others and direct them to achieve organizational goals.

It is important to be organized and efficient in order to meet tight deadlines.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

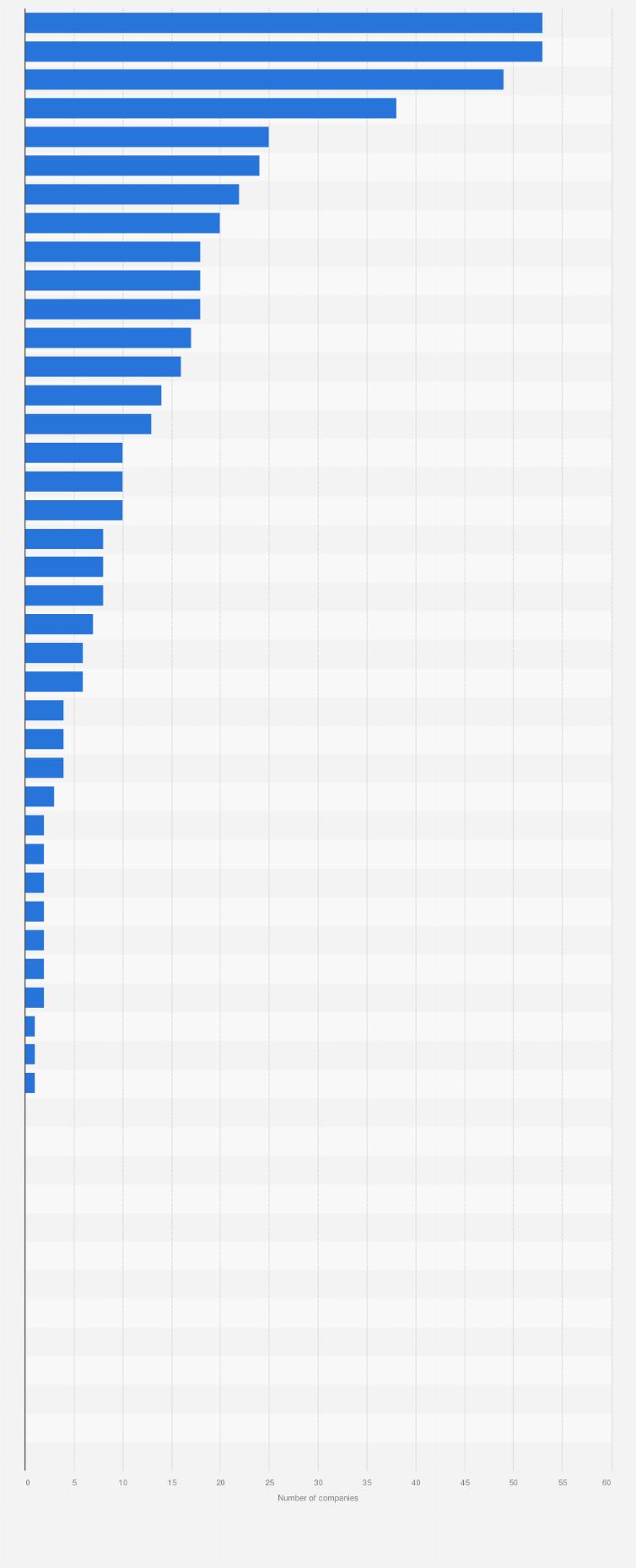

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use lean manufacturing in the Production of Goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was first developed in Japan in the 1970s/80s by Taiichi Ahno, who was awarded the Toyota Production System (TPS), award from KanjiToyoda, the founder of TPS. Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It emphasizes the elimination and minimization of waste in the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Many industries worldwide use lean manufacturing. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Five fundamental principles underlie lean manufacturing.

-

Define Value - Identify the value your business adds to society and what makes you different from competitors.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow - Make sure work runs smoothly without interruptions.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many companies have adopted lean manufacturing methods to increase their marketability. According to some economists, lean manufacturing could be a significant factor in the economic recovery.

Lean manufacturing has many benefits in the automotive sector. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

It can be applied to any aspect of an organisation. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three main types:

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT stands for a system where components are assembled on the spot rather than being made in advance. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. Repairing a part that is damaged during assembly should be done, not scrapping. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.