Six-sigma principles can be used to improve productivity and efficiency in a company. They also reduce cost and improve product. The process can be done through various strategies and methodologies, such as process mapping, statistical analysis, and control charts.

What are the six sigma principles?

The 6 Sigma principles are a series of methods for identifying and eliminating manufacturing defects. They can be implemented in many ways, and the results can be huge. The can also be used to ensure that every process runs smoothly and efficiently.

Lean six sigma:

Understanding the actual workflow is a key principle in lean six-sigma. To be able determine where improvements can be made, you will need to observe and note the process. This is a very important step because it allows you to determine the problem and create a solution.

This is a key principle for all types of projects, but it is particularly important in the process improvement area. It's difficult to implement change when you don't understand what needs to be fixed.

It may be necessary for a company to change the way it works or how its employees approach a task in order to improve its process. It can be difficult to change a process, but with the right attitude, it can be done quickly and efficiently.

Empowering employees to participate in the project is a key principle of six sigma. The main reason for this is that it can be extremely difficult to implement any changes with only upper management on board.

In addition to ensuring that all employees are onboard with the changes, it is important that they are trained in the specific principles of the process so that they can identify and eliminate errors or defects. You should provide the necessary tools and resources to enable them to be involved in the project.

What are six-sigma values?

Six Sigma values focus on customer satisfaction and loyalty, believe that each process should be designed for minimal waste, and place an emphasis on measuring and analysing data. These factors are all important in achieving a high level of satisfaction and loyalty from customers.

Lastly, the six sigma values involve consistency and reliability. These are important factors in an industry that demands high-quality products and services. These should be implemented in every aspect of the company.

The six sigma principles help improve the efficiency of organizations and their operations. These values are essential for a company's growth and success. These are great ways to keep the company competitive and profitable.

FAQ

What skills are required to be a production manager?

To become a successful production planner, you need to be organized, flexible, and able to multitask. It is also important to be able communicate with colleagues and clients.

How can efficiency in manufacturing be improved?

First, determine which factors have the greatest impact on production time. Next, we must find ways to improve those factors. If you don’t know how to start, look at which factors have the greatest impact upon production time. Once you've identified them all, find solutions to each one.

What are the four types in manufacturing?

Manufacturing is the process by which raw materials are transformed into useful products through machines and processes. It includes many different activities like designing, building and testing, packaging, shipping and selling, as well as servicing.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to Use Lean Manufacturing for the Production of Goods

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was first developed in Japan in the 1970s/80s by Taiichi Ahno, who was awarded the Toyota Production System (TPS), award from KanjiToyoda, the founder of TPS. Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It emphasizes eliminating waste and defects throughout the value stream. The five-steps of Lean Manufacturing are just-in time (JIT), zero defect and total productive maintenance (TPM), as well as 5S. Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing improves product quality and costs. It also helps companies reach their goals quicker and decreases employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing is widely used in many industries. Toyota's philosophy has been a key driver of success in many industries, including automobiles and electronics.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define Value- Identify the added value your company brings to society. What makes you stand out from your competitors?

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize & Simplify - Make processes as consistent and repeatable as possible.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many businesses have adopted lean manufacturing techniques to help them become more competitive. According to some economists, lean manufacturing could be a significant factor in the economic recovery.

Lean manufacturing is becoming a popular practice in automotive. It has many advantages. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

It can be applied to any aspect of an organisation. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three main types of lean manufacturing:

-

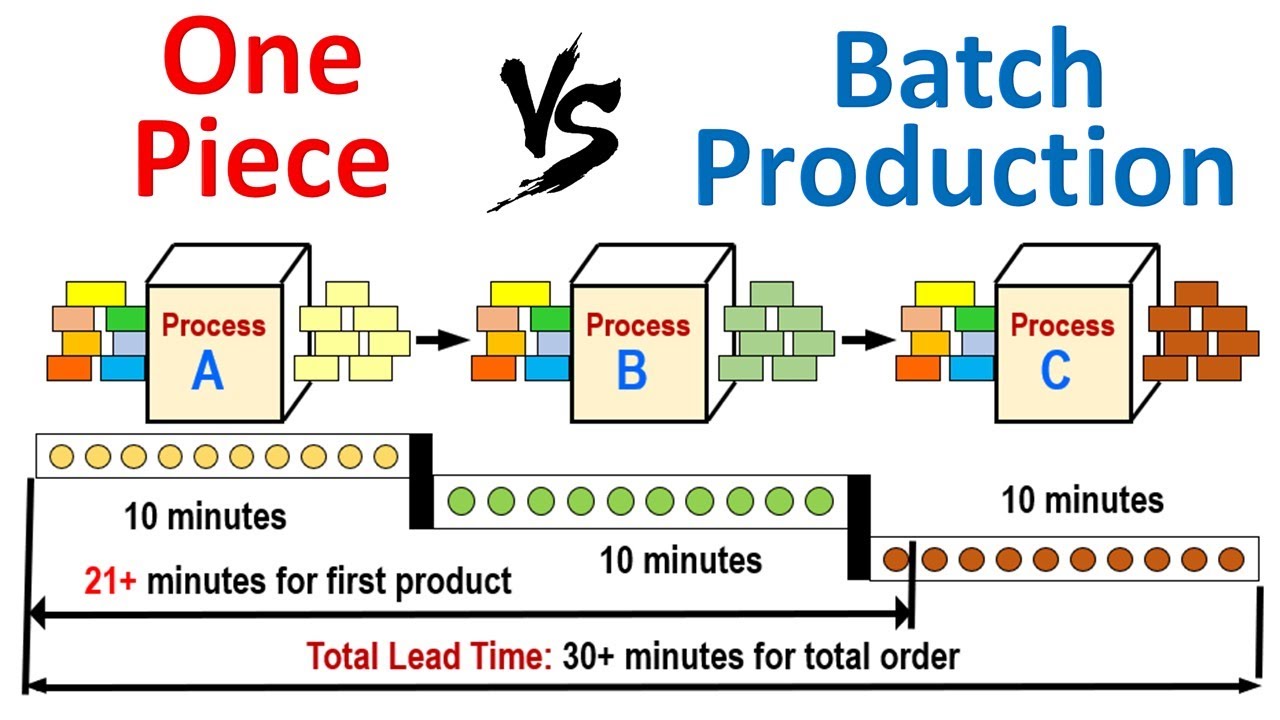

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT means that components are assembled at the time of use and not manufactured in advance. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous Improvement involves continuous improvement of processes.