Your business' success depends on the management of your supply chain. It is important to improve efficiency and customer satisfaction, as well as reduce costs. These benefits are not the only ones. Managing your supply chain can help you increase revenue and give you a competitive edge in the market. A strong supply chain management system can increase revenue by 8% of the ten largest companies.

In order to manage your supply-chain, you must keep track of where your inventory is located and monitor its status. You will also need to know what your products are available, their prices, and how long it takes for them to arrive.

The supply-chain is an interdependent network of people and organizations, technologies and resources that work together in order to produce, transport, deliver and collect goods and services. This network helps organizations produce and ship goods more efficiently and better than ever before. It also reduces production and purchasing costs. It is crucial for the production and distribution of electronic goods, health care products, and other items that are essential for daily living.

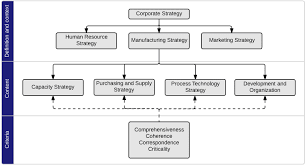

Supply chain management involves the planning and execution of the processes that transport goods from their raw materials to the final consumer. It involves coordination of many different activities such as sales, marketing, production, and distribution. It also includes a system of managing returns for defective products.

Supply chain complexity rises as global competition grows. This increases can be caused by talent attrition, offshoring, part prices fluctuations, and talent erosion. You may also have multiple suppliers to your organization, which can increase redundancy in your supply chains.

Supply chain management encompasses many departments within your company, including finance and sales, operations and manufacturing. This allows you to reduce costs, make your customers happy and deliver products and services more quickly.

You need to be proficient in each of the five components of supply chain management to manage your supply chain effectively. These elements include the design of your supply chain plan, the selection of suppliers, the management of your supplier relationships, the design of your inventory management, and the coordination of your supply chain logistics.

A supply chain planning plan is a plan that describes how your organization will implement the strategy. The plan also contains a breakdown of each step involved in achieving it. You may decide to outsource manufacturing. That includes packaging, distribution, and shipping. In addition, you may need to inspect finished goods and collect payments from customers.

Designing your supply chain plan should include considerations for managing your supplier relationships. One example is a vendor that has a history of delivering goods on-time. A vendor who is flexible may be a good choice, as you will have the ability to purchase emergency supplies in an emergency.

The supply chain management process can help reduce the wear on your equipment. This can help you and your company stay more connected to your customers and decrease quality issues.

FAQ

What is the responsibility of a manufacturing manager?

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They should also be aware and responsive to any company problems.

They should also know how to communicate with other departments such as sales and marketing.

They should be informed about industry trends and be able make use of this information to improve their productivity and efficiency.

How can I learn about manufacturing?

Hands-on experience is the best way to learn more about manufacturing. You can read books, or watch instructional videos if you don't have the opportunity to do so.

What is the role of a production manager?

Production planners ensure that all project aspects are completed on time, within budget and within the scope. They make sure that the product and services meet client expectations.

Is it necessary to be familiar with Manufacturing Processes before we learn about Logistics.

No. You don't have to know about manufacturing processes before learning about logistics. It is important to know about the manufacturing processes in order to understand how logistics works.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

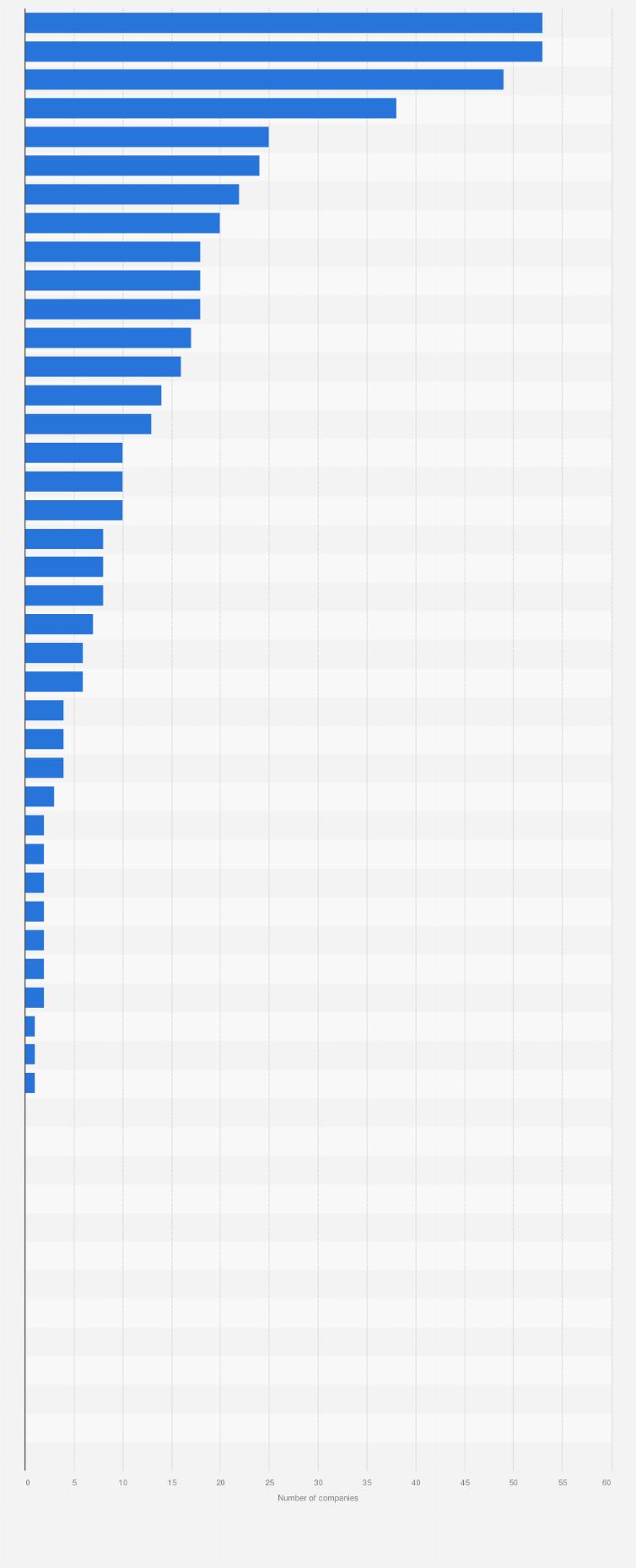

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

Six Sigma and Manufacturing

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. The main goal of Six Sigma is to reduce variation from the mean value of production. It is possible to measure the performance of your product against an average and find the percentage of time that it differs from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you've understood that, you'll want to identify sources of variation. You'll also want to determine whether these variations are random or systematic. Random variations occur when people do mistakes. Symmetrical variations are caused due to factors beyond the process. Random variations would include, for example, the failure of some widgets to fall from the assembly line. But if you notice that every widget you make falls apart at the exact same place each time, this would indicate that there is a problem.

Once you've identified where the problems lie, you'll want to design solutions to eliminate those problems. That solution might involve changing the way you do things or redesigning the process altogether. You should then test the changes again after they have been implemented. If they fail, you can go back to the drawing board to come up with a different plan.