Los Angeles logistics projects can range in size from small warehousing to large courier jobs. Your team will work together to ensure your shipments are delivered on time.

GoodFirms will help you locate the top supply chain and logistic companies in any area.

Our extensive database and research will allow us to help you narrow the list down. Our team can even warn you about companies to stay away from.

Los Angeles's Optimum Recruitment Supply Chain is your go-to source for all things logistics and supply chains. Our team can help you find the right candidate for your position, whether you are looking for a Senior Sales Representative or a Vice President of Logistics.

Top-rated Los Angeles Logistics Company

We design and operate global supply chains and logistics solutions as a leading 3PL provider. Our services include global freight forwarding and customs management, as well as shipment consolidation and deconsolidation.

Logistics & Shipping Specialist Job Openings in Los Angeles

We have thousands of job vacancies available for warehouse staff, logistics managers and logisticians. Our free job board lists the latest openings in the transportation and logistics industry. We're proud to partner with the top employers in the country and are dedicated to finding you the best possible job.

Los Angeles, CA - Logistics Manager

The average annual salary for a logistics manager in Los Angeles is $57K. The city has 1,240 available logistics manager positions, but it takes a certain set of skills to make yourself stand out. The best logistics managers have an eye for the details and a dedication to their team. In addition to a solid track record, your qualifications must also include leadership, customer service and problem-solving skills.

FAQ

What are the essential elements of running a logistics firm?

You need to have a lot of knowledge and skills to manage a successful logistic business. For clients and suppliers to be successful, you need to have excellent communication skills. You must be able analyze data and draw out conclusions. You will need to be able handle pressure well and work in stressful situations. To increase efficiency and creativity, you need to be creative. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

You should also be organized and efficient to meet tight deadlines.

What skills should a production planner have?

To become a successful production planner, you need to be organized, flexible, and able to multitask. You must also be able to communicate effectively with clients and colleagues.

Do we need to know about Manufacturing Processes before learning about Logistics?

No. No. Knowing about manufacturing processes will help you understand how logistics works.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

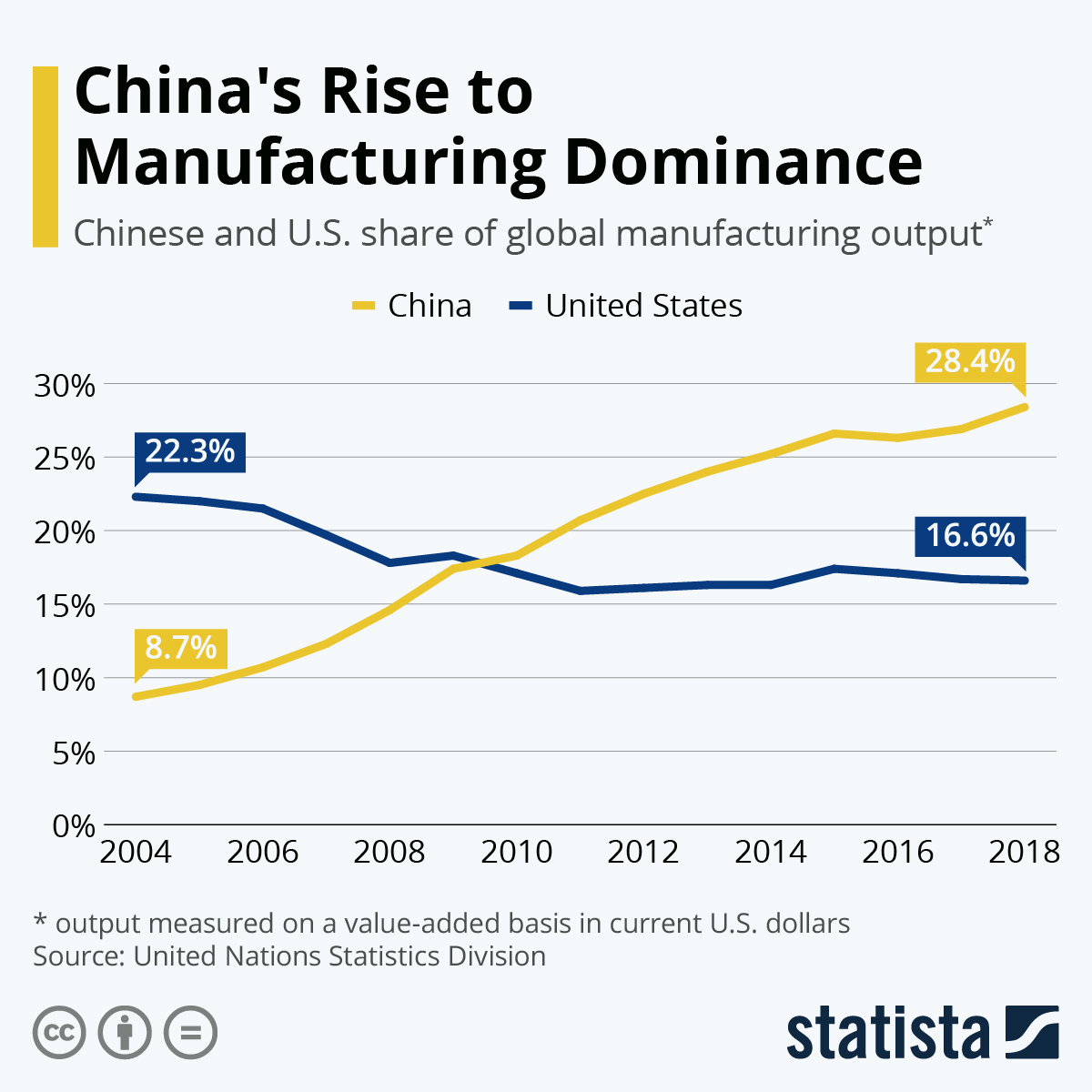

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to use lean manufacturing in the production of goods

Lean manufacturing (or lean manufacturing) is a style of management that aims to increase efficiency, reduce waste and improve performance through continuous improvement. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing is often described as a set if principles that help improve the quality and speed of products and services. It emphasizes eliminating waste and defects throughout the value stream. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing improves product quality and costs. It also helps companies reach their goals quicker and decreases employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing can be found in many industries. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define Value- Identify the added value your company brings to society. What makes you stand out from your competitors?

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many businesses have adopted lean manufacturing techniques to help them become more competitive. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing, which has many benefits, is now a standard practice in the automotive industry. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

It can be applied to any aspect of an organisation. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three types of lean manufacturing.

-

Just-in Time Manufacturing (JIT), also known as "pull system": This form of lean manufacturing is often referred to simply as "pull". JIT means that components are assembled at the time of use and not manufactured in advance. This strategy aims to decrease lead times, increase availability of parts and reduce inventory.

-

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. It is better to repair a part than have it removed from the production line if it needs to be fixed. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI: Continuous improvement aims to increase the efficiency of operations by constantly identifying and making improvements to reduce or eliminate waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.