Manufacturing Phoenix is an Arizona company that provides a range of products to the federal government. It also offers products similar to those offered to commercial clients and individuals. The dedicated facility allows production to be done under one roof with all resources within walking distance. The company also provides employment opportunities for disabled people for over 40 year. It employs approximately 70 people in its manufacturing segment.

Honeywell Aerospace

Honeywell Aerospace is a Phoenix-based aerospace company that creates innovative transportation solutions. Its products, services, and safety features improve flight safety, increase fuel efficiency, and enhance runway traffic. Its products can be found in nearly all commercial airliner. Honeywell Aerospace was also instrumental in the development and production of 2001: A Space Odyssey. Honeywell Aerospace also makes systems for International Space Station.

In 2016, Honeywell opened a Phoenix reactive metal alloy manufacturing plant. The facility converted an outdated flame spray facility in order to produce parts made of titanium or aluminium alloys. Honeywell intends to start producing Inconel 718 parts in this facility by 2017. The facility is home to more than $25 million of investment by Honeywell.

Raytheon Technologies Corp.

Raytheon Technologies Corp. (multinational aerospace and defense conglomerate) is headquartered at Arlington, Virginia. The company is one of the largest manufacturers of military equipment in the world. Its products include aircraft, rockets, missiles, and more. Raytheon is a world-leading aerospace and defense manufacturer. However, it also develops innovative technologies for commercial purposes.

Raytheon is a well-known name in the aerospace and defense sectors. The company's aeronautical navigation systems division is responsible for 27.4%. It also produces mechanical and electrical equipment for aircraft.

Benchmark Electronics

Benchmark Electronics has its headquarters in Tempe, Arizona. It is a contract electronic manufacturing company. With more than 13,000 employees around the globe, the Phoenix-based ODM ranks among the top in the world. The company has offices located in Tempe, Scottsdale and Tempe Marketplace and Gayla Delly has been promoted to CEO.

Vertically integrated engineering and manufacturing services are offered by the Phoenix manufacturing facility. Its capabilities include embedded electronics design, microwave and radio frequency components, as well as high-frequency circuits. It also provides aftermarket solutions. It serves a wide variety of customers within the defense, industrial and commercial aerospace markets.

FAQ

What does warehouse refer to?

A warehouse is a place where goods are stored until they are sold. It can be an outdoor or indoor area. It could be one or both.

What is the responsibility of a manufacturing manager?

A manufacturing manager must make sure that all manufacturing processes run smoothly and effectively. They must also be alert to any potential problems and take appropriate action.

They should also know how to communicate with other departments such as sales and marketing.

They must also keep up-to-date with the latest trends in their field and be able use this information to improve productivity and efficiency.

Is automation important for manufacturing?

Not only is automation important for manufacturers, but it's also vital for service providers. They can provide services more quickly and efficiently thanks to automation. In addition, it helps them reduce costs by reducing human errors and improving productivity.

What is the distinction between Production Planning or Scheduling?

Production Planning (PP) refers to the process of determining how much production is needed at any given moment. Forecasting demand is one way to do this.

Scheduling refers the process by which tasks are assigned dates so that they can all be completed within the given timeframe.

What types of jobs can you find in logistics

There are different kinds of jobs available in logistics. Some examples are:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transportation drivers - They drive trucks and trailers to deliver goods and carry out pick-ups.

-

Freight handlers - They sort and pack freight in warehouses.

-

Inventory managers - These are responsible for overseeing the stock of goods in warehouses.

-

Sales reps - They sell products and services to customers.

-

Logistics coordinators: They plan and manage logistics operations.

-

Purchasing agents - They purchase goods and services needed for company operations.

-

Customer service representatives are available to answer customer calls and emails.

-

Shipping clerks: They process shipping requests and issue bills.

-

Order fillers – They fill orders based upon what was ordered and shipped.

-

Quality control inspectors – They inspect incoming and outgoing products to ensure that there are no defects.

-

Others – There are many other types available in logistics. They include transport supervisors, cargo specialists and others.

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

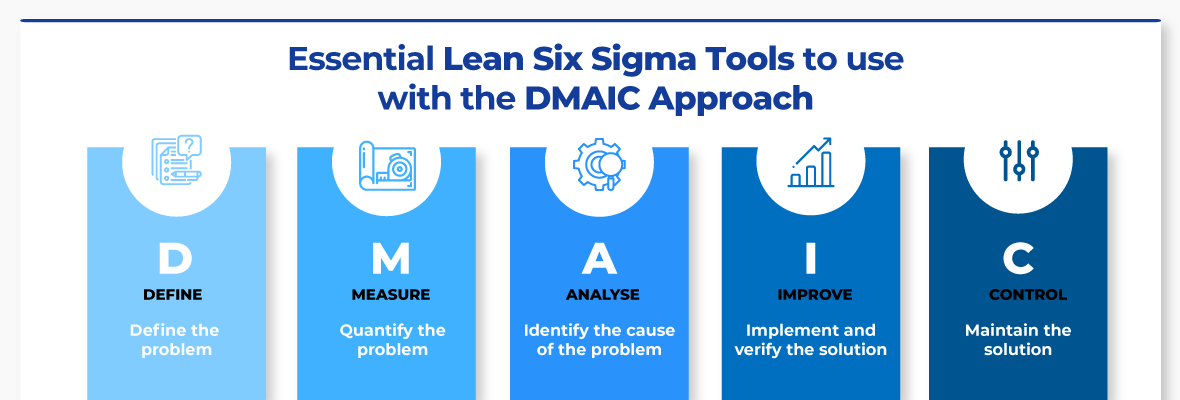

Six Sigma: How to Use it in Manufacturing

Six Sigma is defined by "the application SPC (statistical process control) techniques to achieve continuous improvements." Motorola's Quality Improvement Department, Tokyo, Japan, developed it in 1986. Six Sigma's main goal is to improve process quality by standardizing processes and eliminating defects. Since there are no perfect products, or services, this approach has been adopted by many companies over the years. Six Sigma aims to reduce variation in the production's mean value. You can calculate the percentage of deviation from the norm by taking a sample of your product and comparing it to the average. If you notice a large deviation, then it is time to fix it.

Understanding how your business' variability is a key step towards Six Sigma implementation is the first. Once you've understood that, you'll want to identify sources of variation. Also, you will need to identify the sources of variation. Random variations are caused by human errors. Systematic variations can be caused by outside factors. If you make widgets and some of them end up on the assembly line, then those are considered random variations. You might notice that your widgets always fall apart at the same place every time you put them together.

Once you have identified the problem, you can design solutions. That solution might involve changing the way you do things or redesigning the process altogether. You should then test the changes again after they have been implemented. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.