DFSS (Design for Six Sigma), a design methodology, uses a variety of methods to design a product or service. Its purpose is to reduce waste and improve quality while increasing market share. This is an effective methodology that can help you improve your products and services.

DFSS refers to a design process that considers customer needs throughout the entire process. This ensures that the product/service you design is most appropriate for the customer. It also ensures that your product has a high level of quality when it is introduced to the market. DFSS is used often to design a product/service from scratch. It can also be used in the design of products and/or services to replace or enhance existing products.

In the first phase, the DFSS team determines what the customer needs and wants. This can involve gathering information, interviewing customers, or surveying customers. In order to find the best product or design, the design team reviews other products and designs. This phase also includes the development of substitute concepts and classifying functional requirements. The phase could include additional steps depending on the project's complexity.

DFSS (Design Methodology for Service Design) is a method that aids companies in designing products and services more efficiently. It can also be used to identify potential issues before they become serious problems. It will also reduce waste and increase your company's profitability. It is designed to improve the effectiveness of a product/service by identifying processes that make it more efficient.

There are different methodologies for implementing DFSS. The most common is the DMADV method, which uses a five-step process. It starts with defining the customer, identifying their needs, and developing a design concept. This method is based on solid engineering principles and is used often to develop completely new products or services. It also includes a measurement-and-analysis phase to assess the product’s performance.

The optimization stage is the second phase. This involves evaluating the product's performance at multiple levels. This step is particularly useful when developing new business processes. This stage aims to reduce variability and ensure stability over time.

Verification is the final stage. This is used often to confirm that the product's stability. This step will also confirm that the product's capability has been tested and proven over time. This process also includes validation testing. This step usually takes place after the design has become valid.

In order to successfully implement DFSS, you need to have a detailed process map that shows the different workflows involved in the design process. You should also have details on resources, timeframes, and milestones. It is also important to be able identify any external involvement. You may need to develop a pilot prototype to ensure that the product meets all of the customer's needs. It is also helpful to implement DFSS in an environment that has clear rewards for meeting the goals of the project.

FAQ

What are the main products of logistics?

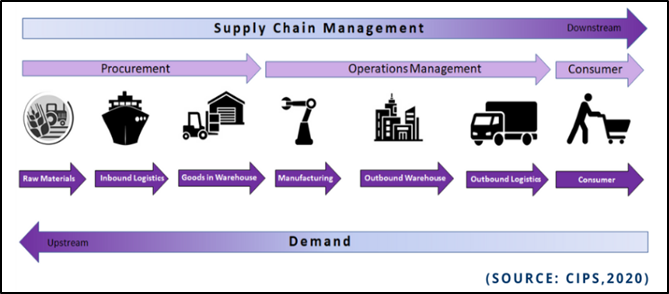

Logistics involves the transportation of goods from point A and point B.

These include all aspects related to transport such as packaging, loading and transporting, storing, transporting, unloading and warehousing inventory management, customer service. Distribution, returns, recycling are some of the options.

Logisticians make sure that the right product arrives at the right place at the correct time and in safe conditions. Logisticians help companies improve their supply chain efficiency by providing information about demand forecasts and stock levels, production schedules, as well as availability of raw materials.

They coordinate with vendors and suppliers, keep track of shipments, monitor quality standards and perform inventory and order replenishment.

What is the responsibility of a production planner?

A production planner makes sure all project elements are delivered on schedule, within budget, as well as within the agreed scope. They make sure that the product and services meet client expectations.

Why is logistics important in manufacturing?

Logistics are essential to any business. They are essential to any business's success.

Logistics are also important in reducing costs and improving efficiency.

What jobs are available in logistics?

There are many jobs available in logistics. Here are some:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transportation drivers – They drive trucks or trailers to transport goods and perform pick-ups.

-

Freight handlers: They sort and package freight in warehouses.

-

Inventory managers - These are responsible for overseeing the stock of goods in warehouses.

-

Sales reps - They sell products and services to customers.

-

Logistics coordinators: They plan and manage logistics operations.

-

Purchasing agents are those who purchase goods and services for the company.

-

Customer service agents - They answer phone calls and respond to emails.

-

Ship clerks - They issue bills and process shipping orders.

-

Order fillers: They fill orders based off what has been ordered and shipped.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

What is production planning?

Production Planning is the creation of a plan to cover all aspects, such as scheduling, budgeting. Location, crew, equipment, props and other details. This document is designed to make sure everything is ready for when you're ready to shoot. It should also contain information on achieving the best results on set. This information includes locations, crew details and equipment requirements.

First, you need to plan what you want to film. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you have identified the scenes and locations, you can start to determine which elements are required for each scene. For example, you might decide that you need a car but don't know exactly what model you want. In this case, you could start looking up cars online to find out what models are available and then narrow your choices by choosing between different makes and models.

Once you have found the right vehicle, you can think about adding accessories. Do you need people sitting in the front seats? You might also need someone to help you get around the back. You may want to change the interior's color from black or white. These questions will help guide you in determining the ideal look and feel for your car. The type of shots that you are looking for is another thing to consider. Are you going to be shooting close-ups? Or wide angles? Maybe you want to show the engine and the steering wheel. All of these things will help you identify the exact style of car you want to film.

Once you have determined all of the above, you can move on to creating a schedule. A schedule will tell you when you need to start shooting and when you need to finish. Every day will have a time for you to arrive at the location, leave when you are leaving and return home when you are done. So everyone is clear about what they need to do. If you need to hire extra staff, you can make sure you book them in advance. It's not worth paying someone to show up if you haven't told him.

When creating your schedule, you will also need to consider the number of days you need to film. Some projects can be completed in a matter of days or weeks. Others may take several days. When creating your schedule, be aware of whether you need more shots per day. Multiplying takes in the same area will result both in increased costs and a longer time. You can't be certain if you will need multiple takes so it is better not to shoot too many.

Another important aspect of production planning is setting budgets. You will be able to manage your resources if you have a realistic budget. You can always lower the budget if you encounter unexpected problems. However, it is important not to overestimate the amount that you will spend. You will end up spending less money if you underestimate the cost of something.

Production planning can be a complex process. However, once you know how everything works together it will become easier to plan future projects.

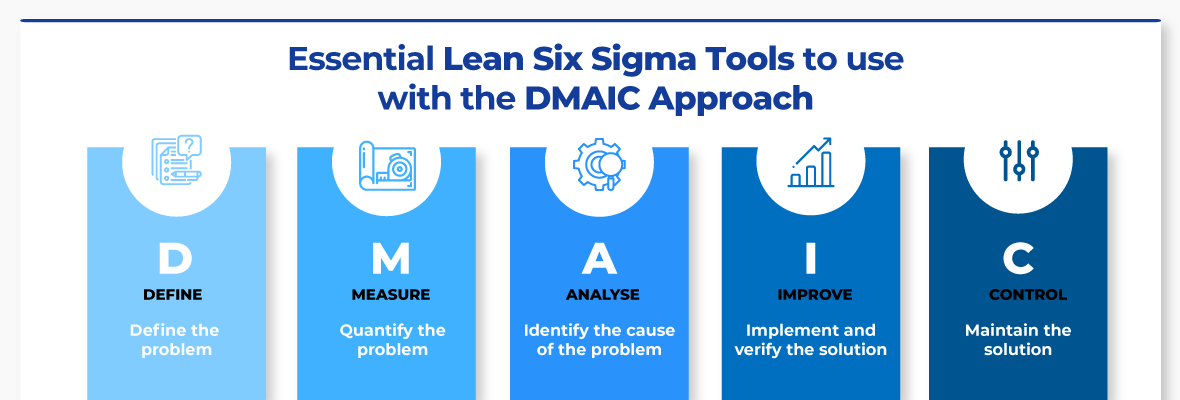

How can manufacturing reduce production bottlenecks?

To avoid production bottlenecks, ensure that all processes run smoothly from the moment you receive your order to the time the product ships.

This includes both planning for capacity and quality control.

This can be done by using continuous improvement techniques, such as Six Sigma.

Six Sigma can be used to improve the quality and decrease waste in all areas of your company.

It is focused on creating consistency and eliminating variation in your work.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to Use 5S for Increasing Productivity in Manufacturing

5S stands as "Sort", Set In Order", Standardize", Separate" and "Store". Toyota Motor Corporation was the first to develop the 5S approach in 1954. This methodology helps companies improve their work environment to increase efficiency.

The idea behind standardizing production processes is to make them repeatable and measurable. This means that every day tasks such cleaning, sorting/storing, packing, and labeling can be performed. This knowledge allows workers to be more efficient in their work because they are aware of what to expect.

Implementing 5S requires five steps. These are Sort, Set In Order, Standardize. Separate. And Store. Each step involves a different action which leads to increased efficiency. If you sort items, it makes them easier to find later. When you arrange items, you place them together. Once you have separated your inventory into groups and organized them, you will store these groups in easily accessible containers. Labeling your containers will ensure that everything is correctly labeled.

Employees will need to be more critical about their work. Employees should understand why they do the tasks they do, and then decide if there are better ways to accomplish them. They must learn new skills and techniques in order to implement the 5S system.

The 5S Method not only improves efficiency, but it also helps employees to be more productive and happier. They are more motivated to achieve higher efficiency levels as they start to see improvement.