Machinists work with a variety of machines. These machines repair metal products like cars. They can also create precision metal parts or new alloys. Toxic substances are common exposure for machinists. A good machinist is meticulous, can communicate well, and can interpret blueprints.

Machinists work either full-time, or part-time. Many of these machinists begin work right out high school. Some machinists do an apprenticeship before moving on to a fulltime job. Others take associate degrees in machining. A few machinists will even go on to study engineering or computer-aided designs (CAD).

Machine operators often work in factories and specialty shops. While these jobs can be noisy and expose to hazardous materials, they also offer excellent opportunities for problem-solving. Machines used by machinists can be manual or automatic. Those with a lot of experience in the field can move up to supervisory or managerial positions. The need for machinists is increasing as baby boomers retire. Job security is also enhanced as machine shops retool to automate.

According to the employer, machinists may be assigned specific tasks, such as setting up and repairing machines or ensuring that their parts meet quality standards. You can also work with assembly lines. These machines are operated by humans and robots. They also have to use a computer for programming and monitoring the machines and interpret blueprints.

Machinists work in a variety of metals, including steel, aluminum brass, copper, and others. While most machinists work with machines that make metal parts, it is not uncommon for them to be required to work with other materials.

Most machinists hold a high-school diploma. However, some employers might require an associate's level. A four-year training program is available for those who are interested in machinist careers. For more experience and knowledge, you may also be able to work with a mentor within your company. Ask your mentor about additional training opportunities, such as apprenticeships and higher education.

Machinists, no matter their employer, must work in a team. They can be part of a team or work alone, but they are usually expected to follow safety procedures. It includes proper safety equipment such earplugs. Also, machinists are frequently exposed to fumes, chemicals, and other environmental hazards. Machinists aren't always under constant pressure.

Machinists can also take college courses, or join trade unions. Machinists with union membership enjoy better benefits and greater job security. Union members have access to health insurance and retirement plans. Numerous colleges offer two year machining associates programs.

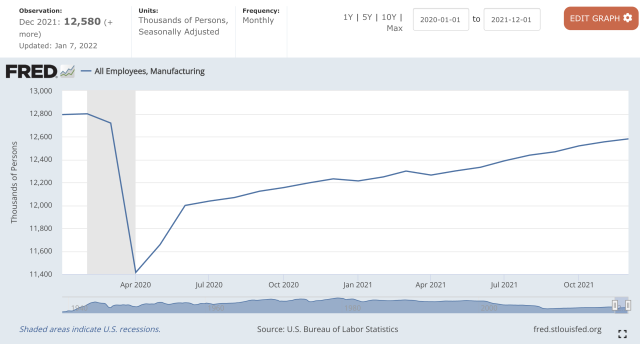

You can rise up the corporate ladder if you have a degree for machinist work. Machinists will be more in demand as car parts become more expensive. Between 2020-2030, there will be a 7% increase in employment. In the coming decades, machinists will remain in high demand due to increased use of artificial Intelligence and retooling of automation.

FAQ

What does it take for a logistics enterprise to succeed?

To run a successful logistics company, you need a lot knowledge and skills. Good communication skills are essential to effectively communicate with your suppliers and clients. You will need to know how to interpret data and draw conclusions. You will need to be able handle pressure well and work in stressful situations. In order to innovate and create new ways to improve efficiency, creativity is essential. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

You should also be organized and efficient to meet tight deadlines.

How can I learn about manufacturing?

Experience is the best way for you to learn about manufacturing. However, if that's not possible, you can always read books or watch educational videos.

What is the responsibility of a logistics manager?

Logistics managers make sure all goods are delivered on schedule and without damage. This is done using his/her knowledge of the company's products. He/she must also ensure sufficient stock to meet the demand.

What does the term manufacturing industries mean?

Manufacturing Industries are those businesses that make products for sale. Consumers are people who purchase these goods. This is accomplished by using a variety of processes, including production, distribution and retailing. They make goods from raw materials with machines and other equipment. This includes all types of manufactured goods, including food items, clothing, building supplies, furniture, toys, electronics, tools, machinery, vehicles, pharmaceuticals, medical devices, chemicals, and many others.

Why is logistics so important in manufacturing?

Logistics are an integral part any business. They are essential to any business's success.

Logistics are also important in reducing costs and improving efficiency.

What skills is required for a production planner?

To become a successful production planner, you need to be organized, flexible, and able to multitask. It is also important to be able communicate with colleagues and clients.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to use Lean Manufacturing in the production of goods

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the "The Machine That Changed the World", the first book about lean manufacturing. It was published in 1990.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It emphasizes reducing defects and eliminating waste throughout the value chain. The five-steps of Lean Manufacturing are just-in time (JIT), zero defect and total productive maintenance (TPM), as well as 5S. Lean manufacturing is about eliminating activities that do not add value, such as inspection, rework, and waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing is widely practiced in many industries around the world. Toyota's philosophy has been a key driver of success in many industries, including automobiles and electronics.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define value - Find out what your business contributes to society, and what makes it different from other competitors.

-

Reduce waste - Stop any activity that isn't adding value to the supply chains.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many companies have adopted lean manufacturing methods to increase their marketability. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

Any aspect of an enterprise can benefit from Lean manufacturing. However, it is particularly useful when applied to the production side of an organization because it ensures that all steps in the value chain are efficient and effective.

There are three main types:

-

Just-in Time Manufacturing (JIT), also known as "pull system": This form of lean manufacturing is often referred to simply as "pull". JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. You should repair any part that needs to be repaired during an assembly line. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.