Mexico was the main actor in the DVA trade network to global manufacturing exports during the analysis period. The automotive sector has not taken the same path as the textiles and apparel industry. Both industries are still considered important in Mexico's export markets and relevant for job creation.

The Mexican automotive industry supplies the United States with the majority of its auto parts. It is also one if the fastest growing sectors in Mexico. However, it has not been able to pull the rest of the economy onto a high expansion trajectory. The transition of the automotive industry from a domestic-oriented sector to a regional parts/automobile chains is actually underway. This is due to a combination regional processes and foreign direct investments.

Many special Mexican development programs have benefited the automotive industry. It has been the top supplier of auto parts in the U.S. and has seen remarkable growth on international markets. Foreign direct investment has been an important factor in the company's rise in global value chain participation.

Mexico's automotive industry is also a major player in the GVCs of Europe, the United States and other countries. Mexico's economy has relied heavily on the automotive industry since the 1970s. However, it hasn't been able to penetrate the global market at the same rate as the textile sector. In addition, it has not achieved a high level of expansion in its output, although it has achieved remarkable penetration into the world market.

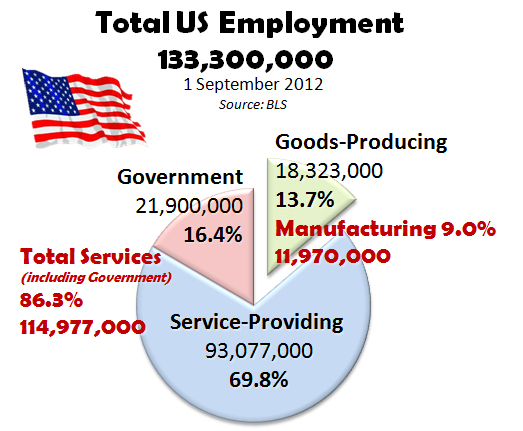

The study uses the framework of decent work indicators developed by the International Labour Organization (ILO) to analyse the relationship between international trade and labour in the manufacturing sector of Mexico. These indicators are based on data from the Mexican government and include links between Mexico's labour regulations and trade agreements. The indicators include an input-output analysis on international trade. This shows that Mexico is a minor player in the value-added domestic manufacturing exports.

This study examines the impacts of trade liberalization in Mexico on employment in the Mexican manufacturing industry. It uses the System of National Accounts to build a set of indicators for decent work in two industrial areas of Mexico. The study constructs a series of indicators over time, and then uses them to analyze the evolution of decent labor in Mexico. The study revealed that D VA G V C levels in the manufacturing industry are significantly lower than those in the textile sector. Similarly, the study finds that the level of employment in the automotive industry is lower than the level of employment in the textile sector. In addition, the study finds that the level of real wages has declined since the beginning of the analysis. In other words, the nominal wage adjustment was not enough to compensate for the deterioration of real wages. The study shows that DVA for exports of equipment transport has increased over the last decade, while DVA for exports of textiles has fallen.

FAQ

How can manufacturing avoid production bottlenecks

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes both planning for capacity and quality control.

Continuous improvement techniques like Six Sigma are the best way to achieve this.

Six Sigma Management System is a method to increase quality and reduce waste throughout your organization.

It is focused on creating consistency and eliminating variation in your work.

What is the distinction between Production Planning or Scheduling?

Production Planning (PP), is the process of deciding what production needs to take place at any given time. Forecasting demand is one way to do this.

Scheduling refers the process by which tasks are assigned dates so that they can all be completed within the given timeframe.

What are the four types of manufacturing?

Manufacturing refers the process of turning raw materials into useful products with machines and processes. Manufacturing can include many activities such as designing and building, testing, packaging shipping, selling, servicing, and other related activities.

Why is logistics important for manufacturing?

Logistics are an essential component of any business. They are essential to any business's success.

Logistics also play a major role in reducing costs and increasing efficiency.

What are the responsibilities of a manufacturing manager

A manufacturing manager must make sure that all manufacturing processes run smoothly and effectively. They should be aware of any issues within the company and respond accordingly.

They should also know how to communicate with other departments such as sales and marketing.

They should also be knowledgeable about the latest trends in the industry so they can use this information for productivity and efficiency improvements.

What are manufacturing and logistics?

Manufacturing is the process of creating goods from raw materials by using machines and processes. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to Use the 5S to Increase Productivity In Manufacturing

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". Toyota Motor Corporation was the first to develop the 5S approach in 1954. It assists companies in improving their work environments and achieving higher efficiency.

The basic idea behind this method is to standardize production processes, so they become repeatable, measurable, and predictable. Cleaning, sorting and packing are all done daily. Because workers know what they can expect, this helps them perform their jobs more efficiently.

There are five steps that you need to follow in order to implement 5S. Each step involves a different action which leads to increased efficiency. You can make it easy for people to find things later by sorting them. You arrange items by placing them in an order. Next, organize your inventory into categories and store them in containers that are easily accessible. Labeling your containers will ensure that everything is correctly labeled.

Employees need to reflect on how they do their jobs. Employees need to understand the reasons they do certain jobs and determine if there is a better way. In order to use the 5S system effectively, they must be able to learn new skills.

The 5S method not only increases efficiency but also boosts morale and teamwork. As they begin to see improvements, they feel motivated to continue working towards the goal of achieving higher levels of efficiency.