Manufacturing Extension Partnership (MEP Centers) provide a range of services designed to help small- and medium-sized businesses grow and thrive. MEP Centers have been established in every state, including Puerto Rico. These centers are trusted business advisors that help solve manufacturers' challenges while identifying opportunities for expansion.

MEP centers hire subject matter experts who have specific knowledge of their local industry and experience assisting small and medium-sized manufacturers in that sector. They can offer assistance in a variety of areas, such as productivity, quality, cybersecurity protection, business growth and advanced technologies. They also create tools that SMMs can use internally or develop with their suppliers, according to Sharon Ohman, senior services manager for Purdue University's MEP center in Fort Wayne.

Centers are funded by federal funds, which pay half to each one. The other half is provided by the state and local governments or private entities. The American Innovation and Competitiveness Act of 2017 adjusted the MEP cost share ratio, allowing the centers to retain more funding from nonfederal sources.

Some MEP centers are run by non-profit organizations, while others are affiliated with universities. Some MEP centers may be operated by the state or a state agency.

These centers are staffed by managers, technicians or consultants. Some centers have more advanced technology and include laboratories or a center for research.

Some centers offer consulting and training services to other businesses. Nebraska MEP supports manufacturers by providing support for implementing new technology.

MEP services may be delivered directly to the employees of a manufacturing company or to that company. Some centers employ specialists who visit a manufacturing facility to discuss specific goals with the leadership team of a manufacturer.

MEP centres have been able to connect with more than 3000 manufacturers during the past 12 months. In the past year, MEP centers have connected with more than 3,000 manufacturers.

The MEP National Network includes 51 MEP Centers (including the NIST MEP Office) and an MEP Board. These partners have an important role to play in the success of the MEP system by helping to ensure that the MEP system remains effective and has the capacity to expand its reach to U.S. manufacturers in the future.

MEP Network provides MEP centers with information infrastructure, and through pilots it helps smaller manufacturers gain access to the technical knowledge they require to run their companies. These projects aim at accelerating the adoption of electronic business by MEP Centers and smaller Manufacturers.

In addition, the MEP National Network is a key component of a larger national strategy to increase the capacity of small and medium-sized manufacturers to adopt technology to support their business and economic growth. The MEP National Network connects with more than 7,000 manufacturers a year, and its work is helping to increase innovation, job creation and economic growth in the United States.

FAQ

What is the role of a production manager?

A production planner makes sure all project elements are delivered on schedule, within budget, as well as within the agreed scope. They ensure that the product or service is of high quality and meets client requirements.

What is production management?

Production planning is the process of creating a plan that covers all aspects of production. This includes scheduling, budgeting and crew, location, equipment, props, and more. This document is designed to make sure everything is ready for when you're ready to shoot. This document should include information about how to achieve the best results on-set. This includes location information, crew details, equipment specifications, and casting lists.

The first step in filming is to define what you want. You may already know where you want the film to be shot, or perhaps you have specific locations and sets you wish to use. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. You might decide you need a car, but not sure what make or model. This is where you can look up car models online and narrow down your options by choosing from different makes and models.

Once you have found the right vehicle, you can think about adding accessories. What about additional seating? Maybe you need someone to move around in the back. You might want to change your interior color from black and white. These questions will help to determine the style and feel of your car. Another thing you can do is think about what type of shots are desired. You will be filming close-ups and wide angles. Maybe you want to show the engine and the steering wheel. These details will help identify the exact car you wish to film.

Once you have determined all of the above, you can move on to creating a schedule. A schedule will tell you when you need to start shooting and when you need to finish. Each day will include the time when you need to arrive at the location, when you need to leave and when you need to return home. So everyone is clear about what they need to do. You can also make sure to book extra staff in advance if you have to hire them. You don't want to hire someone who won't show up because he didn't know.

Also, consider how many days you will be filming your schedule. Some projects may only take a couple of days, while others could last for weeks. It is important to consider whether you require more than one photo per day when you create your schedule. Multiple takes of the same location will lead to higher costs and take more time. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Budgeting is another important aspect of production planning. As it will allow you and your team to work within your financial means, setting a realistic budget is crucial. It is possible to reduce the budget at any time if you experience unexpected problems. However, it is important not to overestimate the amount that you will spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Production planning is a detailed process. But, once you understand the workings of everything, it becomes easier for future projects to be planned.

What do we need to know about Manufacturing Processes in order to learn more about Logistics?

No. No. Understanding the manufacturing process will allow you to better understand logistics.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

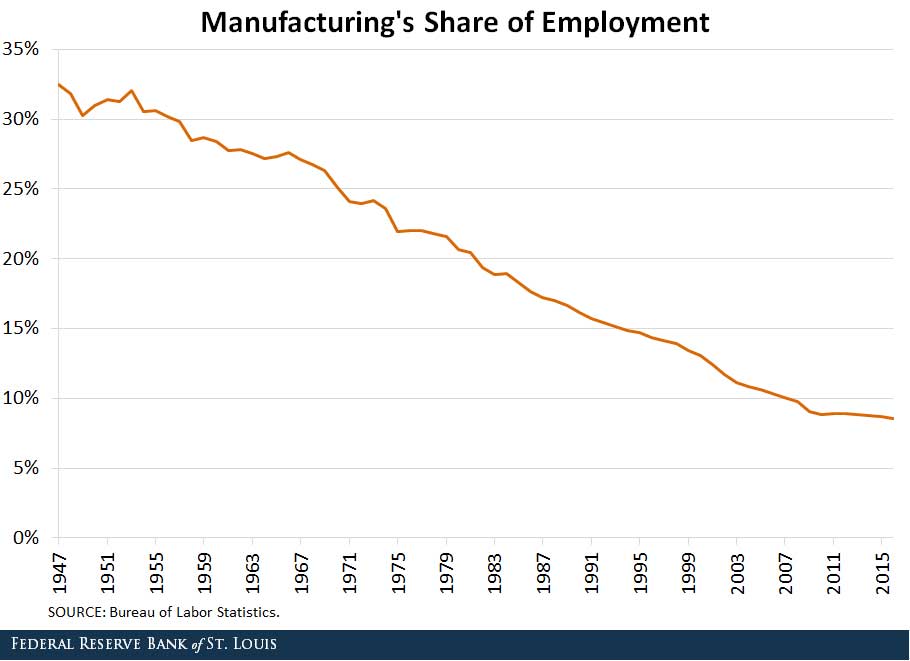

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to Use the Just In Time Method in Production

Just-in-time is a way to cut costs and increase efficiency in business processes. It allows you to get the right amount resources at the right time. This means that your only pay for the resources you actually use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He saw how overtime was paid to workers for work that was delayed. He concluded that if workers were given enough time before they start work, productivity would increase.

JIT is a way to plan ahead and make sure you don't waste any money. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. You will have the resources and people to solve any problems you anticipate. This will prevent you from spending extra money on unnecessary things.

There are many JIT methods.

-

Demand-driven: This type of JIT allows you to order the parts/materials required for your project on a regular basis. This will allow for you to track the material that you have left after using it. This will allow to you estimate the time it will take for more to be produced.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows for you to anticipate how much you can sell.

-

Project-driven: This is an approach where you set aside enough funds to cover the cost of your project. Knowing how much money you have available will help you purchase the correct amount of materials.

-

Resource-based JIT : This is probably the most popular type of JIT. This is where you assign resources based upon demand. For instance, if you have a lot of orders coming in, you'll assign more people to handle them. You'll have fewer orders if you have fewer.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based: This approach is very similar to the cost-based method except that you don't look at individual workers costs but the total cost of the company.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based: Another variation of resource-based JIT. Instead of focusing only on how much each employee is costing, you should focus on how long it takes to complete your project.

-

Quality-based JIT: Another variation on resource-based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based JIT: One of the most recent forms of JIT. You don't worry about whether the products work or if they meet customer expectations. Instead, your focus is on the value you bring to the market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. It is used when production goals are met while inventory is kept to a minimum.

-

Just-in-time planning (JIT): This is a combination JIT and supply-chain management. It's the process of scheduling delivery of components immediately after they are ordered. It reduces lead times and improves throughput.